high-quality

T-SHIRT PRINTING

At Kalox Studio, we work alongside the best and most professional printing centers to offer our clients the most demanding six common ways t-shirt printing methods. This includes Direct-to-garge (DYG), Screen Printing, Dye Sublimation, Heat Transfer Vinyl (HTV), Plastisol Heat Transfer, and Airbrushing.

Direct-to-Garment Printing (DTG Printing)

As the name implies, direct-to-garment is a t-shirt printing technique that applies inks directly to t-shirts, and this distinguishes it from t-shirt printing techniques that apply inks indirectly using a screen or a transfer paper.

DTG printing takes images directly from computer files, allowing you to customize your designs without creating new screens or stencils. You can print complex designs with vibrant colors, high resolution, and sharpness. You can use DTG on most popular t-shirt fabrics, including cotton, polyester, and cotton/polyester blends. It produces the best results on natural fabrics such as cotton.

Screen Printing

The screen printing technique, also called silkscreen printing, applies ink designs to shirts by pressing ink through a mesh partly blocked off by a stencil printing shape. Using a mesh medium classifies screen printing as an indirect t-shirt printing method.

Screen printing was once the most popular printing method for making t-shirts. However, the time it takes to prepare stencils and screens makes screen t-shirt printing less cost-efficient than DTG for small quantities of shirts. Screen printing retains its value for large print runs of hundreds or thousands of t-shirts.

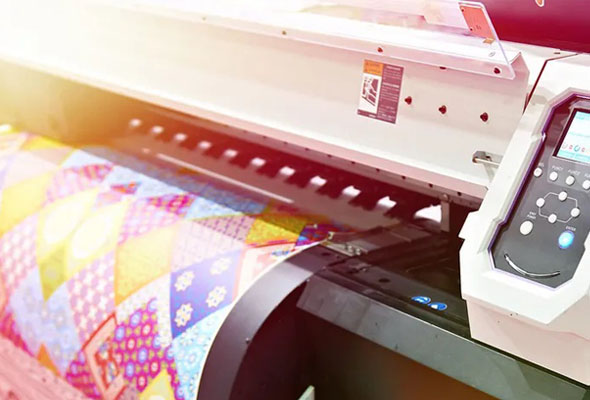

Dye Sublimation Printing

Dye sublimation is also known as all-over printing (AOP) because you can apply it to all shirt areas. For example, dye sublimation can print repeated patterns or cover areas such as seams. It differs from DTG and silkscreen printing techniques, which apply ink to designated printing areas on flat shirt surfaces.

The dye sublimation method uses a three-step process: The t-shirt design is created in a digital image file. A particular printer prints the image in reverse on transfer paper. The paper is pressed to the t-shirt, heated under pressure to a gaseous state, and then cooled, transferring the ink to the shirt.

Sublimation works beautifully on synthetic fabrics such as polyester. However, this printing method doesn’t bond ink to cotton

Heat Transfer Vinyl Printing

Heat transfer vinyl printing, also known as iron-on printing, transfers designs from vinyl plastic-based sheets. You color one side of the sheet with removable tape and cut it into design shapes. You coat the other side with an adhesive activated by heating.

HTV uses a five-step process: The cut pattern is created manually or digitally. The design is cut out by hand or with an HTV cutting machine. Excess material is removed by cutting (weeding). The design is applied to the t-shirt using an iron or heat press. The tape is peeled away to leave the image behind.

The vinyl used in HTV printing creates stiff designs. Heat transfer printing requires fabrics that won’t melt when heated. It doesn’t show up well on dark backgrounds. Many often use HTV printing techniques for lettering on sports jerseys.

Plastisol Transfer Printing

Plastisol screen printing is an indirect screen printing technique that uses a plastic-based transfer sheet to transfer ink to t-shirts. It is a simpler variation of silkscreen printing that applies inks to heat transfer paper instead of a mesh screen.

Plastisol printing uses steps similar to screen printing, with some crucial differences. The most significant difference is that the design is applied to the transfer paper rather than directly to the t-shirt: Created designs and screens are set up as in screen printing, except you do the design in reverse. The transfer paper is run through a conveyor dryer to remove moisture. The transfer paper is placed under the screen. Ink is applied to the transfer paper. The transfer paper is applied to the t-shirt with a heat press. Adhesion powder is applied to the t-shirt to reduce blurring. Remove any excess powder. The ink is heated to gel in a conveyor dryer. A heat press is applied. The transfer paper is peeled off.

Airbrushing

Airbrushing is a manual t-shirt fabric paint method that uses a small spray painting tool. The process involves four steps: A stencil is created from a material such as a pennant felt and attached to a t-shirt using a temporary, light adhesive to hold it in place. You may use multiple stencils for multiple colors. The airbrush is loaded with paint and attached to an air source. For multi-colored designs, use various paints. With the t-shirt on a board and an easel, the airbrush applies paint to the shirt, one color at a time. You may add manual touches as desired. Paperback paper is applied to protect the design and use an iron to set the paint after it dries.

Airbrushing is easy and inexpensive, allowing complete artistic freedom when applying designs. However, airbrushed designs don’t allow intricate detail, and they aren’t durable. The manual labor involved in airbrushing makes it unsuited for large orders.